Welcome back to Tech Tuesday!

Today we’re getting into Carbon Laminate Technology. We’ll talk about why we use carbon fiber, how we use carbon fiber, and the history behind adding carbon to snowboards.

Carbon Laminate: Extremely lightweight, yet stronger than steel

Before we dive into the reasons we use carbon fiber, and all the different ways we incorporate it into our snowboards, we should probably clarify exactly what carbon fiber is. Carbon fiber is made of thin, crystalline filaments of carbon that build strength when twisted together to create a fiber. Those fibers can then be woven together to form a cloth-like material, or if needed to take a permanent shape, can be laid over a mold and coated in plastic or resin.

If you’d like to get deeper into it, the manufacturing process for carbon fiber is pretty interesting. It starts off with the raw material, called precursors, which are made up of organic polymers categorised by long strands of molecules bonded together by carbon atoms. In the manufacturing process, the precursors, are drawn into long, thin fibers. Through an intense process of heating the precursor fibers past 2000º centrigrade while pressurized in an oxygen-free furnace, the noncarbon atoms vibrate and detach themselves from the fiber, while the carbon atoms bond together to form a tight crystalline structure that attaches parallel to the long axis of the fiber. The product of this is the thin, crystalline filaments of carbon mentioned above, that are then woven into the carbon fiber material.

Fun Facts About Carbon Fiber:

– Carbon fiber is five times stronger than steel, and twice as stiff

– Each fiber (before being woven) is 5-10 microns in diameter. To give you perspective on that, a strand of spider web is between 3 - 8 microns.

– The wind-energy industry is now the largest carbon fiber industry in the world, narrowly beating out the aerospace industry as of late 2020.

Carbon fibers are an extremely lightweight material with a high tensile strength, and are very strong for their size. Because of the unique atomic bonding process used to create it, it is also a fairly expensive material, especially in comparison to the alternative fiber glass. However, when it comes to snowboard technology, the unmatched strength and lightweightedness make carbon fiber the obvious choice.

Never Summer Carbon Laminate Technology Throughout the Years

In 1999, Never Summer became the first snowboard company to market and mass-produce snowboards with Carbon V Technology. Before this, carbon had been used in snowboards, but it was usually one large stringer through the center of the board. Creating the V shape, running from the inserts to the effective edge, allows the board to stay softer between the feet, while stiffening the board torsionally, and assists in engaging your edge. This helps you trench turns and keep an edge hold, as well as get that ‘snappy’ back-and-forth turn initiation, ensuring the snowboard moves exactly how you want.

Over the years, Never Summer continued making improvements to their carbon layups, using carbon strategically to strengthen our boards and give them more energy. Carbon has caught on in the snowboard market since then as well and is used widely in snowboard production today.

We dug up some of our old catalogs with Carbon Laminate Technology announcements, check it out:

Carbon Laminate gives your snowboard ENERGY!

Carbon fiber is an extraordinary material to use in snowboard construction because of the rigidity it provides, while remaining lightweight. It can be used in a multiude of ways throughout the board to add stability, increase edge-hold, and transfer energy for better pop and snappy turns.

You ever go to pop off a jump, only for your tail to give out under you? Carbon keeps the board rigid and loads the pop so that you can launch off the lip of the jump with full power. The same goes for landing - nothing worse that wheelying or washing out on your landings. Using Carbon Vs in the nose and tail provide more pop, while adding stabilization to stomp the landing.

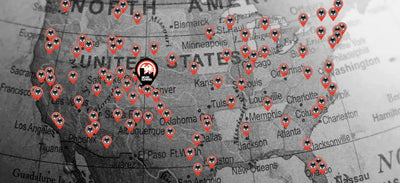

Never Summer Carbon Laminate Technology

These days at Never Summer, we use five primary Carbon Laminate layup methods, either on their own or in combination with one another. Each Never Summer snowboard is different, so if you’re curious about the Carbon Laminate Technology in a specific board, be sure to check out the details on each snowboard page.

CARBON VXR LAMINATE TECHNOLOGY

CARBON VXR extends carbon fiber V's out from the inserts to the effective edge for quick response while stiffening the board torsionally in that area. Originating from the binding mounting zones, Carbon V's engage the edge for quick repsonse. Additionally, V's are positioned to the ends of the board providing maximum boost and pop when loaded up. This is an ideal layup to transfer energy to the end of the effective edge, tip/tail and still give the board a softer more forgiving mid-flex for torsional control. You can find Carbon VXR in models such as the Proto Slinger, Snowtrooper, and Infinity, among others.

See below for an example of a Carbon VXR Laminate:

CARBON MAX LAMINATE TECHNOLOGY

More carbon equals more power and performance. The CARBON MAX LAMINATE TECHNOLOGY combines an advanced top and bottom carbon matrix to maximize response and strength where it's needed most. The result is a lightweight yet powerful configuration that provides torsional rigidity and energy transfer without sacrificing the control a rider needs. You can find Carbon MAX technology in several models, including the entire Shaper Series, as well as this season’s all-new Easy Rider, though the stringers are placed slightly different in the snowboards.

See below for an example of a Carbon MAX Laminate, found in the Shaper Series and the Easy Rider:

Above: Carbon MAX in the Shapeshifter and the rest of the Shaper Series.

Below: Carbon MAX layup found in the Easy Rider.

RECLUSE CARBON WEB TECHNOLOGY

Carbon Fiber is bound in 20-degree angles to add torsional stability to the board, along with longitudinal rebound, enhancing edge hold pressure. The RECLUSE CARBON WEB TECHNOLOGY holds the integrity of the board's flex pattern over a longer period of time and creates powerful snap in and out of the turn.

See below how Recluse Carbon Web can be used either on it's own, or in combination with additional carbon:

Above: Recluse Carbon Web Layup used in the Valhalla.

Below: Recluse Carbon Web Technology uses in combination with Carbon Vs on the Lady FR.

RECLUSE-MAX CARBON TECHNOLOGY

New for the 2024 season in the Proto Synthesis, we have Recluse-Max Carbon, which we’ve briefly covered in another Tech Tuesday. This layup combines a recluse carbon web on the top of the core, along with carbon stringers on the base of the board. New for this year, we've added additional carbon stringers, going from three strips to five strips. This provides even more explosive pop and torsional responsiveness than the Proto Synthesis had before and also makes the Proto Synthesis an industry leader, with more carbon than any other board on the market.

See below for what that looks like inside the Proto Synthesis:

ECDS - ELASTOMERIC + CARBON DAMPING SYSTEM

Our newest edition, Elastomeric + Carbon Dampening System (ECDS) combines carbon fiber and rubber damping strips. Carbon Fiber strands are positioned from the binding mounting area toward the ends of the board, additionally, broad elastomeric rubber damping strips are layed on top of the carbon fiber. This stabilizes the board at high speeds and through choppy or variable snow conditions, while absorbing residual vibration or flutter in the nose and tail.You’ll find this system exclusively on our flagship freeride board, the Proto FR.

Power Strip Carbon, found in the 2020 lineup on the Shade and Dipstick, was the precedent that led to what is now ECDS Technology.

Here's a look at ECDS found exclusively in the Proto FR:

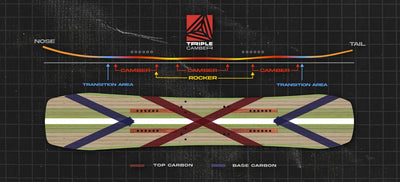

Carbon Laminate Technology Makes Your Board Stronger, Snappier, BETTER.

Carbon Laminate has a ton of benefits in snowboard construction, and we continue to evolve the way we use it to build boards with quick response, incredible edge hold, and powerful energy and pop.

If you want to try a snowboard out before you go all-in, find a Never Summer Demo Day at a resort near you - or if you find yourself in the Denver area, drop by our factory for a tour and see the Carbon get placed in the board for yourself!

Check out our snowboards